1. INTRODUCTION

Pervious concrete which is also known as no fines, porous, gap

graded, and permeable concrete and enhance porosity concrete has been found to

be a reliable storm water management tool. By definition, pervious concrete is

a mixture of gravel or granite stone, cement, water, little to no sand (fine

aggregate). When pervious concrete is used for paving, the open cell structures

allow storm water to filter through the pavement and into the underlying soils.

In other words, pervious concrete helps in protecting the surface of the

pavement and its environment.

Pervious concrete has the same basic constituents as conventional

concrete that is 15% -30% of its volume consists of interconnected void

network, which allows water to pass through the concrete. High range water

reducer and thickening agent are introduced in the concrete to improve its

strength and workability. It can allow the passage of 0.014-0.023 m3 of water

per minute through its open cells for each square foot 0.0929 m2 of surface area

which is far greater than most rain occurrences. Pervious concrete is rough

textured, and has a honeycombed surface, with moderate amount of surface

ravelling which occurs on heavily travelled roadways. Carefully controlled

amount of water and cementitious materials are used to create a paste. The

paste then forms a thick coating around aggregate particles, to prevent the

flowing off the paste during mixing and placing. Using enough paste to coat the

particles maintain a system of interconnected voids which allow water and air

to pass through. The lack of sand in pervious concrete results in a very harsh

mix that negatively affects mixing, delivery and placement. Also, due to high

void content pervious concrete is light in weight (about 1600 to 1900kg/m3).

Pervious concrete void structure provides pollutant captures which also add

significant structural strength as well. It also results in very high permeable

concrete that drains quickly.

Pervious concrete can be used in a wide range of applications,

although its primary use in pavements which are in: residual roads, alleys and

driveways, low volume pavements, low water crossings, sidewalks and pathways,

parking areas, tennis courts, slope stabilization, sub-base for conventional

concrete pavements etc.

Pervious concrete system has advantages over impervious concrete

in that it is effective in managing run-off from paved surfaces, prevent contamination

in run-off water, and recharge aquifer, repelling salt water intrusion, control

pollution in water seepage to ground water recharge thus, preventing

subterranean storm water sewer drains, absorbs less heat than regular concrete

and asphalt, reduces the need for air conditioning. Pervious concrete allows

for increased site optimization because in most cases, its use should totally

limit the need for detention and retention ponds, swales and other more

traditional storm water management devices that are otherwise required for

compliances with the Federal storm water regulations on commercial sites of one

acre or more. By using pervious concrete, the ambient air temperature will be

reduced, requiring less power to cool the building. In addition, costly storm

water structures such as piping, inlets and ponds will be eliminated.

Construction scheduling will also be improved as the stone rechargebed will be

installed at the beginning of construction, enhancing erosion control measures

and preventing rain delays due to harsh site conditions. Apparently, when

compared to conventional concrete, pervious concrete has a lower compressive

strength, greater permeability, and a lower unit weight (approximately 70% of

conventional concrete). However, pervious concrete has a greater advantage in

many regards. Nevertheless, it has its own limitation which must be put in

effective consideration when planning its use. Structurally when higher

permeability and low strength are required the effect of variation in aggregate

size on strength and permeability for the same aggregate cement ratio need to

be investigated.

Fig 1.1 Pervious Concrete

2. PREPARATION OF PERVIOUS CONCRETE

CONSTITUENTS OF CONCRETE

If a constituent is to be suitable for a particular purpose, it is

necessary to select the constituent materials and combine them in such a manner

as to develop the special qualities required as economical as possible. The

selection of materials and choice of method of construction is not easy, since

many variables affect the quality of the concrete produced, and both quality

and economy must be considered. The characteristics of concrete should be

evaluated in relation to the required quality for any given construction

purpose.

2.1 CEMENT

Ordinary Portland cement, 53 grade conforming to IS: 269 – 1976.

Ordinary Portland cement, 53 grade was used for casting all the specimens.

Different types of cement also will produce concrete have a different rates of

strength development. The choice of brand and type of cement is the most

important to produce a good quality of concrete. The type of cement affects the

rate of hydration, so that the strengths at early ages can be considerably

influenced by the particular cement used.

2.2 COARSE AGGREGATE

Locally available crushed blue granite stones conforming to graded

aggregate of nominal size 12.5 mm as per IS: 383-1970. Several investigations

concluded that maximum size of coarse aggregate should be restricted in

strength of the composite. In addition to cement paste – aggregate ratio,

aggregate type has a great influence on concrete dimensional stability.

2.3 WATER

Casting and curing of specimens were done with the portable water

which is available.

3. STRUCTURAL PERFORMANCE OF PERVIOUS CONCRETE

For the evaluation of the structural performance of the pervious

concrete in civil engineering construction, the effects of varying the

aggregate size on thecompressive strength and permeability and durability of

pervious concrete were studied. This study covers the simple use of pervious concrete

as pavement material in the construction of pedestrian walkways and parking

lots.

3.1 PREPARATION OF TEST SPECIMEN

Three batches of test specimen were produced from each of the

aggregate size representing aggregate cement ratios of 6:1, 8:1 and 10:1 with

no fines in the mixes. The materials were batched by weight as in Table3.1. As

earlier stated, two different sizes of coarse aggregate (crushed stone or

granite) were used in this study. The sizes are 3/8-inch (9.375mm) and 3/4-inch

(18.75mm) granite. The specific gravity test carried out on the two aggregate

sizes gave average value of 2.7. For the two aggregate sizes, the mix

proportions were done by weight. From each of the batches, 8 of 150mm concrete

cubes were taken. The mix proportioning are as shown in Table 3.1.

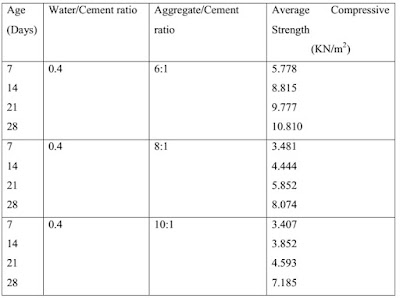

Table 3.1 Mix Proportion by Weight of Aggregate and Cement

The batched materials are thoroughly hand-mixed with water so as

to obtain uniform and homogenous pervious concrete. Water/cement ratio of 0.4

was added to form a cement paste, ACI 211.3R (2002) stipulates that the ratio

should be between 0.35 and 0.45. A total of 24 cubes were produced for each

aggregate size for different mix ratio of 6:1, 8:1 and 10:1 of coarse aggregate

and cement.

3.1.1 COMPRESSIVE STRENGTH TEST

The aim of the test is to determine the compressive strength of

pervious concrete. The test was carried out in accordance with BS1881-108: 1983

and ACI 522R-10. The cubes were tested for compressive strength (Fig 3.2) at

specify ages of 7, 14, 21 and 28 days of curing. The compressive strength of

pervious concrete is calculated thus:

Compressive strength = (crushing load, kN)/(area of cross section, m2)

Compressive strength = (crushing load, kN)/(area of cross section, m2)

Fig 3.2 Compression Testing Machine (Controls Milano-Italy,range: 0- 1500 kN)

The compressive strength of the pervious concrete increases with

increase in age and as the aggregate/cement ratio reduces as observed in Table

3.2 and 3.3. Also, the compressive strength of the 3/8’’ aggregate is greater

than that of 3/4” for the same age and aggregate/cement ratios as shown in

tables 3.2 and 3.3.

Table 3.2 Compressive Strength at age 7, 14, 21, 28 days for 6:1, 8: 1 and 10:1

Aggregate/Cement ratio and aggregate size of ¾”

Table3.3 Compressive Strength at age 7, 14, 21, 28 days for 6:1, 8: 1 and 10:1

Aggregate/Cement ratio and aggregate size of 3/8”

Aggregate/cement ratio of 6:1, 8:1 and 10:1 had compressive

strength of 29%, 18% and 15% respectively of 28N/mm2 which is the maximum value

stipulated by ACI 552R-10 on 28th day of curing for aggregate size 3/4".

In addition, for the same aggregate cement ratio(6:1 ,8:1 and 10:1) the

compressive strength of the concrete were found to be 39%, 29% and 26% of the

value stipulated by ACI 552R-10 which is 28 N/mm2 for aggregate size 3/8”.

Conclusively, the A/C of 6:1 had the highest value of compressive

strength and aggregate size 3/8” produced the best results.

Fig 3.3 Compressive strength of Pervious Concrete of 3/8” Aggregate size at

different Aggregate-Cement Ratio

Fig 3.4 Compressive Strength of Pervious Concrete of 3/4" Aggregate size at

different Aggregate/Cement Ratio

Fig 3.5 Comparison between ¾” and 3/8” Compressive Strength for 6:1

Aggregate/Cement ratio

3.1.2 PERMEABILITY TEST

The permeability of pervious concrete was determined using a

falling head permeability set up Fig 3.6. Water was allowed to flow through the

sample, through a connected standpipe which provides the water head. Before

starting the flow measurement, the samples were wrapped with polythene inside

the cylinder. Then the test started by allowing water to flow through the

sample until the water in the standpipe reached a given lower level. A constant

time of 5 sec was taken for the water to fall from one head to another in the

standpipe. The standpipe was refilled and the test was repeated when water

reached a lower level as shown in Fig 3.6. The permeability of the pervious

concrete sample was evaluated from the expression given below:

Where,

a = the sample cross section area

A = the cross section of the standpipe of diameter (d) = 0.95cm2

L = the height of the pervious concrete sample

(t2- t1) = change in time for water to fall

from one level to another (5secs.)

h1= upper water level

h2= Lower water level

D= diameter of sample (10.5 cm)

d= diameter of standpipe (1.1 cm)

Fig 3.6 Falling head permeability set up

Table 3.4 Permeability result for ¾” aggregate size and A/C Ratio of 6:1

Table 3.5 Permeability result for ¾” aggregate size and A/C Ratio of 8:1

Table 3.6 Permeability result for ¾” aggregate size and A/C Ratio of 10:1

Table 3.7 Permeability result for 3/8” aggregate size and A/C Ratio of 6:1

Table 3.8 Permeability result for 3/8” aggregate size and A/C

Ratio of 8:1

Table 3.9 Permeability result for 3/8” aggregate size and A/C

Ratio of 10:1

Fig 3.7 Variation of average values of K with A/C ratio for 3/8”

and ¾”

aggregate sizes

aggregate sizes

3.2 Durability of pervious concrete

Concrete durability is one of the most important considerations in

the design of new structures and when assessing the condition of existing

structures. Concrete construction is becoming increasingly complex and the

importance of producing structures that are both cost effective and durable has

never been higher. The main purpose of durability is about minimising the rate

of deterioration. Durability of Concrete is related to the design process, specification

of materials, workmanship, environmental effects, accidents and repairs. The

Durability of Concrete is the resistance of concrete to weathering action,

chemical attack, abrasion and other degradation processes. Cylinders of size

100 mm diameter and 200 mm height are made for an experimental investigation of

Durability of Pervious Concrete. Pervious Concrete has been casted with

different concrete mix proportion such as 1:6, 1:8 and 1:10 with 18.75 mm and

9.375 mm gravel size with OPC 53 Grade Cement.

Table 3.10 Physical properties of OPC 53 grade

3.2.1 DURABILITY (Sodium Chloride Solution) TEST: [IS 445:2000]

For the durability test the oven dried specimens having known

volume will be weighted on the digital weighing machine and calculated to the

mass of specimen per unit volume. To investigate the effect of sodium chloride

solution the specimens will be tested for percentage change in weight after 28

days immersion in sodium chloride solution. Percentage change in weight

determination will be carried out in the same manner as of in the water

absorption test. The schedule for casting and testing are as shown in fig 3.8.

Fig 3.8 Cylinders immersed in sodium chloride (NaCl) solution

Table 3.11 Durability test results for cylinder (100mmⱷ &200mm height)

Fig 3.9 Durability of mix A1, A2, A3 after 28 days for 18.75 mm

Fig 3.10 Durability of mix B1, B2, B3 after 28 days for 9.375mm

Ø Pervious concrete made from coarse aggregate size 9.375mm had compressive strength value of 39% compared to that of 18.75mm which is 29% of the maximum value of strength stipulated by ACI 552-R10 (i.e. 28N/mm2) for aggregate cement ratio A/C 6:1. It is clearly seen from the experimental result that Pervious Concrete has very low Compressive Strength as well as Flexural Strength, so it cannot be used for “structural application” but it should be significantly used for so many other applications such as, sidewalks, parking lots, sports surfaces, swimming pool decks, driveways.

Ø As shown in Fig 3.7, and Tables 3.4 – 3.9, the aggregate/cement ratio of 10:1 produced pervious concrete of higher co-efficient of permeability of 3.12x10-3cm/sec and 3.89x10-3cm/sec for aggregate size 9.375mm and 18.75mm respectively.

Ø 18.75 mm size gravel with 1:6 proportion made with OPC is more durable (0.34%) compared to other and similarly 9.375 mm size gravel with 1:6 mix proportion made with OPC is more durable (0.36%) compared to other

4. APPLICATIONS

Pervious concrete paving reduces the runoff from paved areas,

which reduces the need for separate storm water retention ponds and and allows

the use of smaller capacity storm sewers. This allows property owners to develp

a large area of available property at a lower cost. Pervious concrete also

naturally filters storm water and can reduce pollutant loads entering into

streams, ponds and rivers. It captures the first flush of rainfall (the first

30 to minutes of rainfall which will lead to a runoff with most pollutants) and

allows that to percolate into the ground so that soil chemistry and biology can

treat the polluted water. Pervious concrete functions like a storm water

retention basin and allows the storm water to infiltrate the soil over a large

area, thus faciliating recharge of pervious ground water supplies locally. All

of these benefits lead to more effective land use. Pervious concrete can also

reduce the impact of development on trees. A pervious concrete pavement allows

the transfer of both water and air to root systems allowing trees to flourish even

in highly developed areas.

Common applications for pervious concrete are parking lots,

sidewalks, pathways, tennis courts, patios, slope stabilisation, swimming pool

decks, green house floors, zoo areas, shoulders, drains, noise barriers,

friction course for highway pavements, permeable based under a normal concrete

pavement, and low volume roads. Pervious concrete is generally not used solely

for concrete pavements for high traffic and heavy wheel loads.

Fig 4.11 Pervious Concrete Application- Naturepaths

Figure 4.12: Pervious Concrete Application-Driveways

Fig 4.13 Pervious Concrete Application- Sidewalks

5. CONSTRUCTION OF PERVIOUS PAVEMENT

An experienced installer is vital to the success of pervious

concrete pavements. The subgrade is the bed on which the pavements structure is

constructed and can be either native materials or imported fill. As with any

pavement, proper subgrade preparation is important. The subgrade should be

properly compacted to provide a uniform and stable surface. It is important to

examine carefully the soils present on each project for both structural and

drainage capacities before specifying a compaction range since soils differ in

the way compaction affects infiltration rate. The level of compaction is

typically 90% of Standard Proctor Maximum Dry Density (SPMDD). In some cases,

pavement will be placed on a sub base of clean gravel or crushed stone, which

may be used as a storm water storage basin. If the compacted site soils or

imported fill have sufficient percolation rates and the project is not in an

area where freezing and thawing is a concern, then a sub base may not be

required an the pervious concrete can be placed directly on the subgrade. The

project engineer should make this determination based on local regulations,

soil permeability, storm water volume, anticipated traffic loads, and pavement

purpose. If a sub base is used engineering fabrics are used to separate fine

grained soils from the stone layer. The sub grade and sub base should be

moistened prior to concrete placement to prevent the pervious concrete from

setting and drying too quickly. Also wheel ruts from construction traffic

should be raked and re-compacted.

Pervious concrete is sensitive to changes in water content, so

field adjustment of the fresh mixture is usually necessary. The correct quantity

of water in the concrete is critical. Too much water will cause segregation, and

too little water will lead to balling in the mixer unloading. Too low a water

content can also hinder adequate curing of the concrete and lead to a premature

raveling surface failure. A properly proportioned mixture gives the mixture a

wet metallic appearance or sheen. Previous concrete has little excess water in

the mixture. Any time the fresh material is allowed to sit exposed to the

elements is time that it is losing water needed for curing. Drying of the

cement paste can lead to a raveling failure of the pavement surface. All

placement operations and equipment should be designed and selected with this in

mind and scheduled for rapid placement and immediate curing of the pavement. A

pervious concrete pavement may be placed with either fixed forms or slips or

slipform paver. The most common approach to placing pervious concrete is in

forms on grade that have a riser strip on the top of each form such that the

strike off device is actually 3/8-1/2in.(9 to 12mm)above final pavement

elevation. Strike off may be vibraratory or manual screeds. After striking off

the concrete, the riser strips are removed and the concrete compacted by

manually operated roller that bridges the forms. Rolling consolidates the fresh

concrete to provide strong bond between the paste and aggregate and creates a

smoother riding surface. Excessive pressure when rolling should be avoided as

it may cause the voids to collapse. Rolling should be performed immediately

after strike off. Since floating and trowelling tend to close up the top

surface of the voids there not carried out.

Fig 5.14 Compaction of pervious concrete by rolling

Joining pervious concrete pavement follows the same rules as for

concrete slabs on grade, with a few exceptions. With significantly less water

in the fresh concrete, shrinkage of the hardened materials is reduced

significantly, thus, joint spacings may be wider. The rules of jointing

geometry, however, remain the same. Joints in pervious concrete are tooled with

a rolling jointing tool. This allows joints to be cut in a short time, and

allows curing to continue uninterrupted. Saw cutting joints also is possible,

but is not preferred because slurry from sawing operations may block some of

the voids, and excessive raveling of the joints often results. Removing covers

to allow sawing also slows curing, and it is recommended that the surfaces be

re-wet before the covering is replaced. Some pervious concrete pavements are

not joined, as random cracking is not viewed as a significant deficit in the

aesthetic of the pavement (considering the texture), and has no significant

affect on the structural integrity of the pavement.

Proper curing is essential to the structural integrity of a

pervious concrete pavement. The open structure and relatively rough surface of

pervious concrete exposes more surface area of cement paste to evaporation,

making curing even more essential than in conventional concreting. Curing

ensures sufficient hydration of the cement paste to provide the necessary

strength in the pavement section to prevent raveling. Curing should begin

within 20 minutes after final consolidation and continue through 7 days.

Plastic sheeting is typically used to cure pervious concrete pavements.

Fig 5.15 Pervious Pavement

6. MAINTENANCE

Two common preventable problems with pervious concrete are surface

raveling and clogging.

Surface raveling is removal of loose aggregate material from the

pervious concrete surface and is caused by inadequate w/c, inadequate

compaction, or improper curing procedures. Good curing practices, appropriate

w/c (not too low), and adequate compaction is important to reduce raveling.

Where as severe raveling is unacceptable some loose stones on a finished

pavement is always expected. Once the top layer of loose stones is removed

ravelling usually stops. Use of snow ploughs could increase raveling. A plastic

or rubber shield at the base of the plow blade may help to prevent damage to

the pavement.

Clogging is the deposition of fines and vegetative matter on the

pervious concrete surface or in its voids thus reducing its infiltration rates.

Vegetation matter such as leaves can be deposited and may have to be removed

peiodically. Further can be water- bone, wind- borne, or tracked onto the

pervious concrete pavement by traffic. In preparing the site prior to

construction drainage of surrounding landscaping should be designed to pavement

flow of materials onto pavement surfaces.

Due to the very high levels of initial infiltration rate, most

pervious concrete pavements can work well with some amount of clogging .A

recent investigation of several field sites in Southern USA (Wanielista et

al.2007) indicated that pervious concrete pavements that were installed 10 to

15 years ago, with no maintenance requirements, are operating in a satisfactory

manner with insignificant amounts of clogging. The two commonly accepted

maintenance methods are pressure washing and power vaccumming. Pressure washing

forces the contaminants down through the pavement surface. This is effective,

but care should be taken not to use too much pressure, as this will damage the

pervious concrete. Power vacumming removes contaminants by extracting them from

the pavement voids. The most effective scheme, however, is to combine the

techniques and power vaccum after pressure washing.

For a pervious pavement system to perform well, it may need to be

maintained at some regular interval. On a monthly basis, the paving area should

be ensured to be clean of debris or sediments by broom sweeping. Power

vacumming is suggested on an annual basis. For critical projects ASTM C1701

testing could be conducted to evaluate if there is significant clogging and if

there is more advanced measures could be considered. If a pavement is in a

harsh environment, such as a coastal area, or anywhere that would cause heavy

accumulations of fines, it may be necessary to perform this preventative

maintenance more frequently.

7. ADVANTAGES

Ø It reduces the storm water runoff

Ø Eliminates the need for detention ponds and other costly storm water management practices

Ø Replenishes the aquifers and water table

Ø Allows more efficient land development

Ø Prevents water from entering into the stream and also prevents it from being polluted

Ø Less need for storm sewer

Ø Green building alternative suitable for many application

Ø Natural run-off allows rainwater to drain directly to sub-base

Ø Reduced pollution prevents environmental damage

Ø Keeps pavement surfaces dry even in wet situation, such as green houses

Ø Allows water and air to get to the roots of trees within a parking area

Ø Pervious concrete performs noise absorption

Ø Water purifying performance

Ø A parking lot properly constructed from pervious concrete has a life span ten times as long as an asphalt lot, thereby providing excellent long term benefits. It is true that the initial costs for pervious pavement may be slightly higher due to the preparation of the sub-base, but those who look long term will realize the economic benefits

Ø Useful for irrigation that is retain water to be used for irrigation

Ø Lower installation costs due to the elimination of costly curbs, gutters, storm drain outlets and retention basins that cost two to three times more to construct than pervious. Less money will be needed for labor, construction and

maintenance of ponds, pumps, drainage pipes and other storm water management systems.

Ø Allows for the use of existing storm sewer systems for new developments

Ø Lower life-cycle costs equal to that of conventional concrete that if properly constructed will last for 20 to 40 years. Pervious requires fewer repairs than asphalt, and can be recycled once it has reached its lifecycle.

8. DISADVANTAGES

Ø Runoff from adjacent areas onto pervious concrete needs to be prevented.

Ø The parking areas are generally limited to auto parking andoccasional trucks.

Ø If reinforcement is required, epoxy coated bars should beused.

Ø Concrete is variable in permeability; over vibration significantly reduces permeability.

Ø It is still a new material that requires acceptance from cities and states

9. CONCLUSION

Pervious concrete is a cost-effective and environmental friendly

solution to support sustainable construction. Its ability to capture storm

water and recharge ground waterwhile reducing storm water runoff enables

pervious concrete play a significant role. Due to its potential to reduce the

runoff, it is commonly used as pavement material. The smaller the size of

coarse aggregate should be able to produce a higher compressive strength and at

the same time produce a higher permeability rate. The mixtures with higher

aggregate/cement ratio 8:1 and 10:1 are considered to be useful for a pavement

that requires low compressive strength and high permeability rate. The ideal

pervious concrete mix is expected to provide the maximum compressive strength,

and the optimal infiltration rate.

10. REFERENCES

1. S.O. Ajamu, et,al. “Evaluation of Structural Performance

of Pervious Concrete in Construction”, International Journal of Engineering

and

Technology Volume 2 No. 5, May, 2012.

Technology Volume 2 No. 5, May, 2012.

2. Darshan S. Shah , et.al. “Pervious Concrete: New Era For

Rural Road”,

International Journal Of Engineering Trends and Technology (IJETT), Volume 4 Issue 8, August 2013.

International Journal Of Engineering Trends and Technology (IJETT), Volume 4 Issue 8, August 2013.

3. Darshan S, et.al. “An Experimental Study of Durability

and Water Absorbtion Properties of Pervious Concrete”, International Journal

of

Research In Engineering and Technology, eISSN: 2319- 1163, pISSN: 2321- 7308.

Research In Engineering and Technology, eISSN: 2319- 1163, pISSN: 2321- 7308.

4. Darshan S, “An Experimental Study on Hardened Properties

of Pervious Concrete”, Journal Of Engineering Academic Research For Multi

Disciplinary Impact factor 1.393, ISSN:2320-5083, Volume 2, Issue 3, April 2014

Disciplinary Impact factor 1.393, ISSN:2320-5083, Volume 2, Issue 3, April 2014

5. M. Harshavarthana Balaji, et.al. “Design of Eco Friendly

Pervious Concrete”,International Journal Of Civil Engineering and Technology

(IJCIET), Volume 6, Issue2, February (2015)

(IJCIET), Volume 6, Issue2, February (2015)

6. Karthik H. Obla, “Pervious concrete –An overview”, The

Indian Concrete

Journal, August 2010

Journal, August 2010

7. Neetu B. Yadav, et.al. “Pervious Concrete: Solution for

Low Cost Construction”, International Journal of Innovative Science and

Modern

Engineering (IJISME) ISSN: 2319–6386, Volume-1, Issue-10, September 2013

Engineering (IJISME) ISSN: 2319–6386, Volume-1, Issue-10, September 2013

No comments:

Post a Comment